Double Side Ties are recommended as an improvement over Armor Rods secured with hand tie wire and clamp top insulators. When installed with a pad on bare conductor, they provide superior protection against abrasion and all types of conductor motion. The pad is a resilient cushion at the point of contact between conductor and insulator. Double Side Ties are designed for double cross arm conductor support.

1cdb36043d494acdbf40898d27e9e3f2

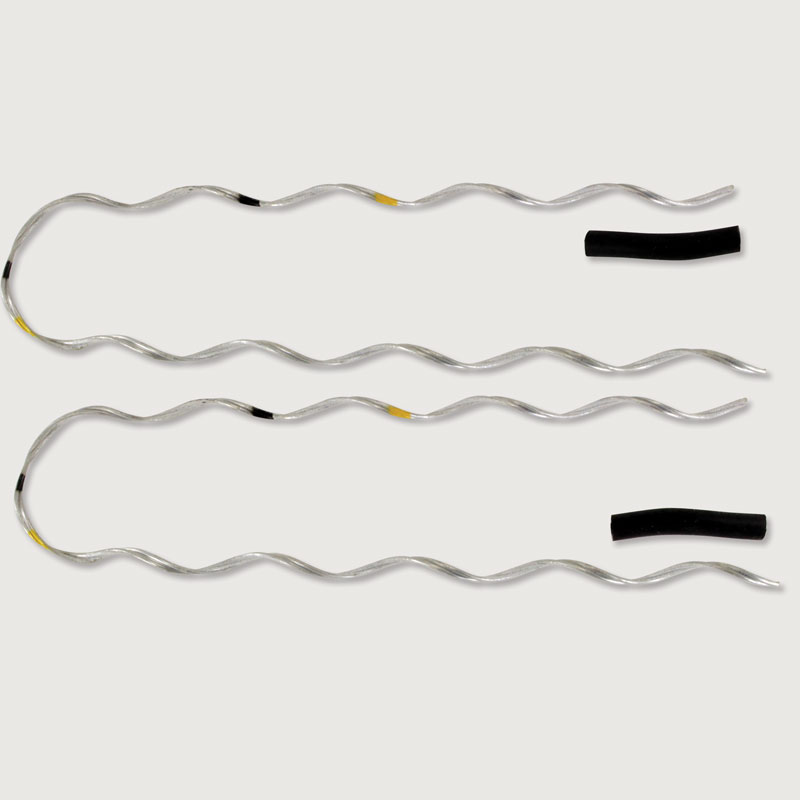

1 Formed Wire Formed Wire © 2014, AFL, all rights reserved. PP-3-00853, Revision 4, 9.7.2021 Specifications are subject to change without notice. AFLglobal.com | 800.866.7385 RUS Approved Double Side Tie MATERIALS Ties - (2 each) Aluminum covered steel. Identification tag - Identifies catalog number, neck size, nominal conductor size, and conductor diameter range. Color code - Indicates the proper conductor diameter range. The C Neck and F Neck Double Side Ties have two color codes. The inner color code indicates the crossover mark for C Neck insulators and the outer color code indicates the F Neck crossover mark. J Neck Double Side Ties have only one color code. Pads - (2 each) Specially formulated elastomer. General Recommendations To insure proper fit and service life, it is recommended that only insulators corresponding to C Neck, F Neck, or J Neck be used. The neck diameters and groove height dimensions appear in ANSI Standard for low and medium voltage pin type insulators. Non-Standard Insulators Double Side Ties are recommended as an improvement over Armor Rods secured with hand tie wire and clamp top insulators. When installed with a pad on bare conductor, they provide superior protection against abrasion and all types of conductor motion. The pad is a resilient cushion at the point of contact between conductor and insulator. Double Side Ties are designed for double cross arm conductor support. Maximum Size Conductor sizes up to 1.20" O.D. can be accommodated depending on the insulator side groove radius. Line Angle At double cross arms, Double Side Ties are recommended for running line angles of up to 30 degrees with no more than 15 degrees at each insulator. Unbalanced Loading Under unbalanced load conditions, the Double Side Tie has the resiliency to permit some longitudinal displacement of the conductor over the insulator without loosening the tie or damaging the conductor. Radio Interference The RIV characteristics of Double Side Ties are superior to those of a well made hand tie when originally installed. During service-life, the pre-contoured helix assures consistent fit which has better RIV characteristics than loosened tie wire. Tapping Tapping over applied legs of the Double Side Tie is not recommended. Taps should be located at least 6 inches from the end of the legs. continued

© 2014, AFL, all rights reserved. PP-3-00853, Revision 4, 9.7.2021 Specifications are subject to change without notice. AFLglobal.com | 800.866.7385 2 Formed Wire Formed Wire RUS Approved Double Side Tie C Neck and F Neck ACSR, All-Aluminum, Aluminum Alloy, AWAC, Compacted All-Aluminum and Compacted ACSR C Neck 2-1/4" Neck Diameter ANSI Class 55-2 and 55-3 F Neck 2-7/8" Neck Diameter ANSI Class 55-4 and 55-5 Pin Type 57-1, 57-2 and 57-3 Post Type Insulator Identification Mark: Black and Yellow AFL NO. DIA. RANGE INCHES NOMINAL CONDUCTOR SIZE UNITS PER CARTON WT. PER CARTON POUNDS APPLIED LENGTH INCHES COLOR CODE DBST 062 .245-.277 #4, 6/1, 7/1 #4, 7W, Aluminum Alloy 50 21 16 Orange DBST 070 .278-.315 #3, 7W, Aluminum Alloy #2, 7W, All Aluminum 50 21 16 Purple DBST 080 .316-.357 #2, 6/1, 7/1 #2, 7W, Aluminum Alloy #11, 6/1 50 21 17 Red DBST 091 .358-.405 1/0, 7W, All Aluminum 1/0, 6/1 1/0, 7W, Aluminum Alloy 50 21 16 Yellow DBST 103 .406-.459 2/0, 7W, All Aluminum 2/0, 6/1 2/0, 7W, Aluminum Alloy 50 21 18 Blue DBST 117 .460-.520 3/0, 7W, All Aluminum 3/0, 6/1 3/0, 7W, Aluminum Alloy 50 36 19 Orange DBST 132 .521-.588 4/0, 7W, All Aluminum 4/0, 6/1 4/0, 7W, Aluminum Alloy 50 36 19 Red DBST 149 .589-.665 266.8, 37W, All Aluminum 266.8,18/1 50 38 20 Purple DBST 169 .666-.755 336.4, 19W, All Aluminum 336.4, 18/1 397.6, 19W, All Aluminum 400, 19W, 37W, All Aluminum 50 39 20 Brown DBST 192 .756-.855 477, 19W, 37W, All Aluminum 477, 18/1, 24/7 50 39 20 Red DBST 217 .856-.968 556.5, 19W, All Aluminum 636, 18/1 700, 37W, 61W, All Aluminum 50 42 22 Blue DBST 246 .969-1.096 795, 37W, All Aluminum 795, 61W, All Aluminum 715.5, 24/7 795, 54/7 50 44 24 Green DBST 278 1.097-1.240 954, 36/1, 54/7 1033.5, 37W, 61W, All Aluminum 50 44 24 Yellow Right-Hand Lay Standard continued

3 Formed Wire Formed Wire © 2014, AFL, all rights reserved. PP-3-00853, Revision 4, 9.7.2021 Specifications are subject to change without notice. AFLglobal.com | 800.866.7385 RUS Approved Double Side Tie J Neck ACSR, All-Aluminum, Aluminum Alloy, AWAC, Compacted All-Aluminum and Compacted ACSR 3-1/2" Neck Diameter ANSI Class 55-6 and 55-7 Single Skirt Pin Type 56-1 Double Skirt Pin Type Insulator Identification Mark: Green AFL NO. DIA. RANGE INCHES NOMINAL CONDUCTOR SIZE UNITS PER CARTON WT. PER CARTON POUNDS APPLIED LENGTH INCHES COLOR CODE DBSTJ 062 .245-.277 #4, 6/1, 7/1 #4, 7W, Aluminum Alloy 50 24 19 Orange DBSTJ 070 .278-.315 #3, 7W, Aluminum Alloy #2, 7W, All Aluminum 50 21 17 Purple DBSTJ 080 .316-.357 #2, 6/1, 7/1 #2, 7W, Aluminum Alloy #1, 6/1 50 27 22 Red DBSTJ 091 .358-.405 1/0, 7W-19W, All Aluminum 1/0, 6/1 1/0, 7W, Aluminum Alloy 50 26 21 Yellow DBSTJ 103 .406-.459 2/0, 7W-19W, All Aluminum 2/0, 6/1 2/0, 7W, Aluminum Alloy 50 36 19 Blue DBSTJ 117 .460-.520 3/0, 7W, All Aluminum 3/0, 6/1 3/0, 7W, Aluminum Alloy 50 37 20 Orange DBSTJ 132 .521-.588 4/0, 7W, All Aluminum 4/0, 6/1 4/0, 7W, Aluminum Alloy 50 39 21 Red DBSTJ 149 .589-.665 266.8, 37W, All Aluminum 266.8,18/1 50 45 24 Purple DBSTJ 169 .666-.755 336.4, 19W, All Aluminum 336.4, 18/1 397.6, 19W, All Aluminum 4W, 19W, 37W, All Aluminum 50 46 25 Brown DBSTJ 192 .756-.855 477, 19W, 37W, All Aluminum 477, 18/1, 24/7 50 44 24 Red DBSTJ 217 .856-.968 556.5, 24/7 636, 18/1 700, 37W, 61W, All Aluminum 50 43 23 Blue DBSTJ 246 .969-1.096 795, 37W, All Aluminum 795, 61W, All Aluminum 715.5, 34/7 795, 54/7 50 43 23 Green DBSTJ 278 1.097-1.240 954, 36/1, 54/7 1033.5, 37W, 61W, All Aluminum 50 48 25 Yellow Right-Hand Lay Standard

Comealongs and HiTemp Comealongs for ACSR AAC AAAC ACAR ACSS and ACSSTW Conductors,AFL Filler Compound,Alnox Electrical Joint Compound,Alnox UG Electrical Joint Compound,HiTemp® AFL Filler Compound (AFCHT™),HiTemp® AFL Universal Compound (HiTUC),No. 2 Electrical Joint Compound,HiTemp® Compression Dead Ends for ACSS Conductors,HiTemp® Compression Dead Ends for ACSS/TW Conductors,HiTemp® Compression Joints for ACSS Conductors,HiTemp® Compression Joints for ACSS/TW Conductors,HiTemp® Compression Jumper for ACSS Conductors,HiTemp® Compression Jumper for ACSS/TW Conductors,HiTemp® Compression Repair Sleeve for ACSS Conductors,HiTemp® Compression Repair Sleeve for ACSS/TW Conductors

2123