Spool Ties not only replace hand ties over armor rods, but Spool Ties with pads provide superior protection against abrasion and all types of conductor motion from high frequency aeolian vibration to low frequency galloping. The pad, which surrounds the conductor is a resilient cushion where the conductor is in contact with the insulator.

1cdb36043d494acdbf40898d27e9e3f2

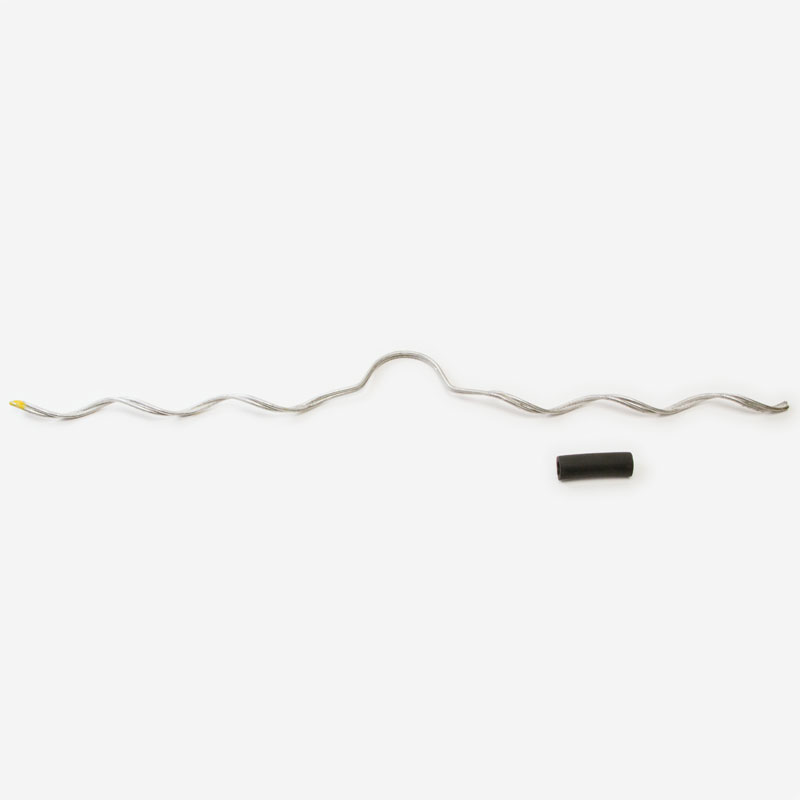

1 Formed Wire Formed Wire © 2014, AFL, all rights reserved. PP-3-00855, Revision 4, 9.7.2021 Specifications are subject to change without notice. AFLglobal.com | 800.866.7385 Quick Spool Tie MATERIALS Ties - Manufactured of aluminum covered steel. Pads - A specially formulated elastomer pad is supplied with each Quick Spool Tie used for bare conductor, identified by catalog number suffix P. To specify the Quick Spool Tie without the pad use the suffix T (for use on jacketed conductor). Identification tag - Identifies catalog number, neck size, nominal conductor size, and conductor size. General Recommendations To insure proper fit and service life, it is recommended that only spool insulators of 1-3/4" neck diameter be used of ANSI class 53-1, 53-2 and 53-3. Spool Ties not only replace hand ties over armor rods, but Spool Ties with pads provide superior protection against abrasion and all types of conductor motion from high frequency aeolian vibration to low frequency galloping. The pad, which surrounds the conductor is a resilient cushion where the conductor is in contact with the insulator. Maximum Size Spool Ties are available for conductor sizes up to 0.968". Line Angle The following are the maximum permissible angles: Unbalanced Loading Under unbalanced load conditions, the Spool Tie has the resiliency to permit some longitudinal displacement of the conductor over the insulator without loosening the tie or damaging the conductor. Radio Interference The RIV characteristics of Spool Ties are superior to those of a well made hand tie when originally installed. During service-life, the pre-contoured helix assures consistent fit which has better RIV characteristics than loosened tie-wire. Tapping Tapping over applied legs of the Spool Tie is not recommended. Taps should be located at least 6 inches from the end of the legs. HORIZONTALLY MOUNTED SPOOL VERTICALLY MOUNTED SPOOL LINE ANGLE 40° 10° continued

© 2014, AFL, all rights reserved. PP-3-00855, Revision 4, 9.7.2021 Specifications are subject to change without notice. AFLglobal.com | 800.866.7385 2 Formed Wire Formed Wire Quick Spool Tie 1-3/4 Neck With Pad ACSR, All-Aluminum, Aluminum Alloy, AWAC, Compacted All-Aluminum and Compacted ACSR Selection Information Quick Spool Tie Numeric Range Code Pad (P=With T=Without) SPL XXX X Spool Insulators ANSI Class 53-1, 53-2, and 53-3 1 3/4"Neck Diameter AFL NO. DIA. RANGE INCHES NOMINAL CONDUCTOR SIZE UNITS PER CARTON WT. PER CARTON POUNDS APPLIED LENGTH INCHES COLOR CODE QSPL 062 P .245 - .277 #4, 6/1, 7/1 #4, 7W, Alum. Alloy 100 16 15 Orange QSPL 070 P QSPL 080 P .316 - .357 #2, 6/1, 7/1 #2, 7W, Alum. Alloy #1, 6/1 100 23 18 Red QSPL 091 P .358 - .405 1/0, 7W, All Alum. 1/0, 6/1 1/0, 7W, Alum Alloy 100 24 20 Yellow QSPL 103 P .406 - .459 2/0, 7W, All Alum. 2/0, 6/1 2/0, 7W, Alum. Alloy 100 28 22 Blue QSPL 117 P .460 - .520 3/0, 7W, All Alum. 3/0, 6/1 3/0, 7W, Alum. Alloy 100 32 24 Orange QSPL 132 P .521 - .588 4/0, 7W, All Alum. 4/0,6/1 4/0, 7W, Alum. Alloy 50 18 25 Red QSPL 149 P .589 - .665 266.8, 37W, All Alum. 266.8, 18/1 50 19 28 Purple QSPL 169 P .666 - .755 336.4, 19W, All Alum. 336.4, 18/1 336.4, 37W, All Alum. 397.5, 19W, All Alum. 400, 19W, 37W, All Alum. 50 24 31 Brown QSPL 192 P .756 - .855 477, 19W, 37W, All Alum. 477,18/1, 24/7 50 25 32 Red QSPL 217 P .856 - .968 556.5, 19W, All Alum. 636, 18/1 700, 37W, All Alum. 50 26 33 Blue

Spool Ties not only replace hand ties over armor rods, but Spool Ties with pads provide superior protection against abrasion and all types of conductor motion from high frequency aeolian vibration to low frequency galloping. The pad, which surrounds the conductor is a resilient cushion where the conductor is in contact with the insulator.

Comealongs and HiTemp Comealongs for ACSR AAC AAAC ACAR ACSS and ACSSTW Conductors,AFL Filler Compound,Alnox Electrical Joint Compound,Alnox UG Electrical Joint Compound,HiTemp® AFL Filler Compound (AFCHT™),HiTemp® AFL Universal Compound (HiTUC),No. 2 Electrical Joint Compound,HiTemp® Compression Dead Ends for ACSS Conductors,HiTemp® Compression Dead Ends for ACSS/TW Conductors,HiTemp® Compression Joints for ACSS Conductors,HiTemp® Compression Joints for ACSS/TW Conductors,HiTemp® Compression Jumper for ACSS Conductors,HiTemp® Compression Jumper for ACSS/TW Conductors,HiTemp® Compression Repair Sleeve for ACSS Conductors,HiTemp® Compression Repair Sleeve for ACSS/TW Conductors

2127